Description

[vc_btn title=”Catalog” style=”3d” color=”black” align=”right” link=”url:http%3A%2F%2Fwww.gccworld.com%2Fdata%2Ffile%2F201804%2F1524183664XM375.pdf||target:%20_blank|”]

[vc_tta_tabs style=”modern” active_section=”1″][vc_tta_section title=”Features” tab_id=”1534199381021-db9e9c66-9a57″]

[/vc_tta_section][vc_tta_section title=”Optional Items” tab_id=”1534199381078-5cada041-3736″ el_class=”Optional items for GCC RX II”]

[/vc_tta_section][vc_tta_section title=”Spec” tab_id=”1534199665227-a968f5bf-a253″ el_class=”Spec for GCC RX II”]

[/vc_tta_section][vc_tta_section title=”Spec” tab_id=”1534199665227-a968f5bf-a253″ el_class=”Spec for GCC RX II”]

[/vc_tta_section][vc_tta_section title=”Video” tab_id=”1534199734817-ad3dbbb5-dd83″ el_class=”GCC RX II vinyl cutter Video”][vc_video link=”https://youtu.be/kbETRq9IgE4″ el_width=”50″ title=”GCC – AAS II (Automatic-Aligning System)Contour Cutting Demo for Expert24 LX”][vc_video link=”https://youtu.be/05iowFPNC4E” el_width=”50″ title=”GCC – RX Series Introduction”][vc_video link=”https://youtu.be/0zFAlAuOg8U” el_width=”50″ title=”GCC – GrateCut installation and operation ” el_class=”GCC – GrateCut installation and operation “][vc_video link=”https://youtu.be/hVaoxxqLGHI” el_width=”50″ title=”GCC – Vinyl Cutter Blade Specification” el_class=”GCC – Vinyl Cutter Blade Specification”][/vc_tta_section][vc_tta_section title=”Software ” tab_id=”1534199998717-93d36ad9-168a” el_class=”GCC vinyl cutters compatibel softwares “]

[/vc_tta_section][vc_tta_section title=”Tech Support” tab_id=”1534200343317-07cc9279-56c7″ el_class=”GCC vinyl cutters tech support”]

[/vc_tta_section][/vc_tta_tabs]

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

Add-on Flat Table (RX II)

For cutting thick sheet material, such as magnet.

18″ x 24″ Low Adhesive Film (3 pcs/pk)

Put materials on the Low Adhesive Film to cut, and it’s recommended to work with Add-on Flat Table.

Wi-Fi Router

Wi-Fi router allows you to transmit data through a wireless network. It can work with GCC laser engravers and RX II/ Jaguar V cutting plotters through the Ethernet port (not applicable for Japanese users.) Whether you are sending files to multiple GCC machines using one PC or sharing one unit of GCC machines with multiple PCs, this wireless technology can be an excellent helper.

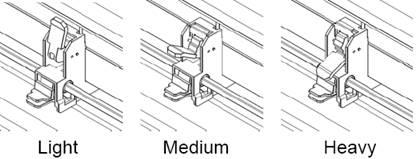

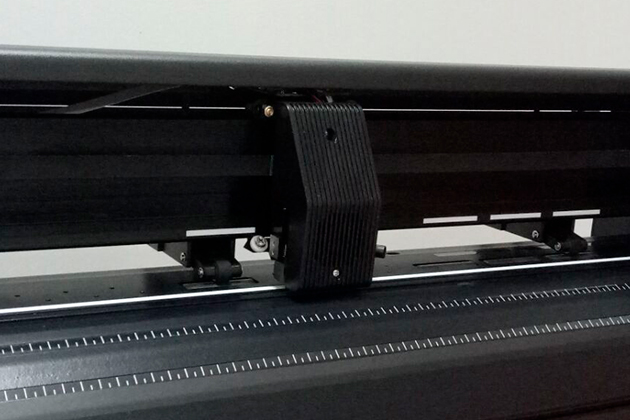

Metallic Blade Holder Φ2.5mm

Adjusting the blade length to fit your needs.

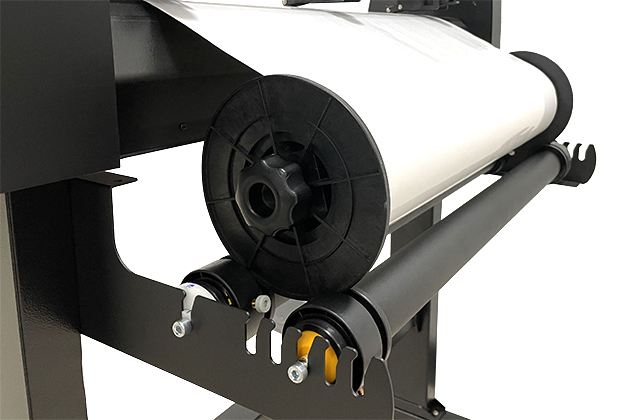

Stand

To support cutting plotter machine and roll media.

Media Basket

To keep your vinyl off the floor and away from dust or contaminants. Your production will be a clean and efficient operation.

Safe Blade

Users can cut off the finished job by the safe blade.

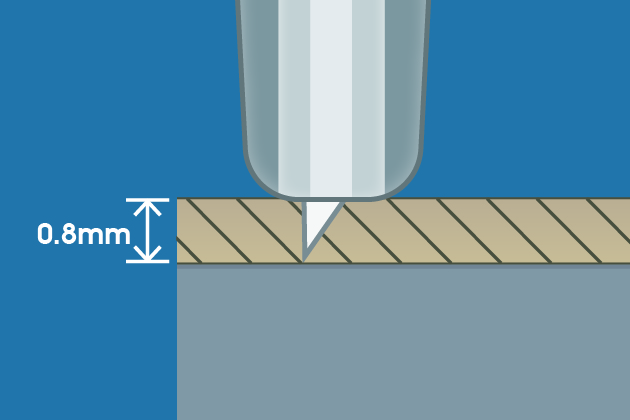

Cutting Blades

Users can replace the cutting blade by different materials to meet your need.

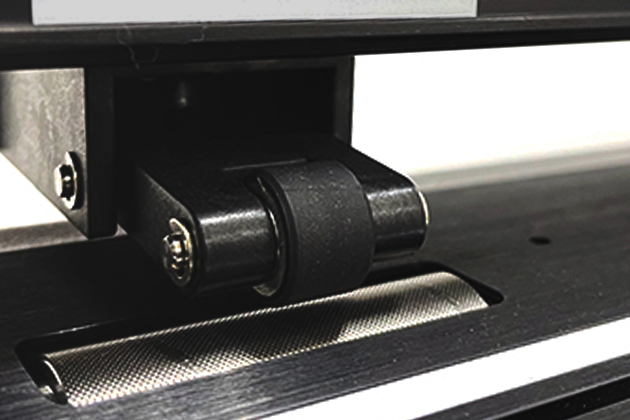

Cutting Pad

It prevents the blades from becoming blunt quickly.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

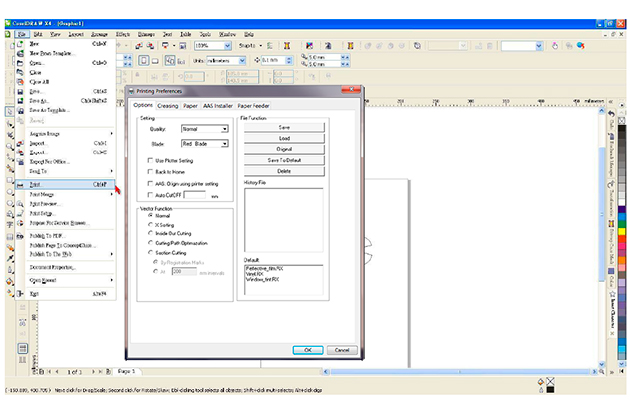

GreatCut

- Professional cut plug-in for Corel DRAW, Illustrator, Freehand, AutoCAD

- Cutting by color

- Registration marks with “Print & Cut” Support

- Plot Manager

- Free bundle with vinyl cutters (for i-Craft™ is an optional item)

Sure Cuts A Lot

- Multi-languages interface

- iOS tablet app Sure Cuts A Lot 3 available (i-Craft™ output only)

- Available for Windows & Macintosh OSX

- Import various file formats, including SVG & PDF

- Works with your installed TrueType & OpenType fonts, as well as thousands of free fonts available on the Internet.

| How to reset SCA License if PC format without deactivate flow ? | download |

| RX_RX II Touch Key and LCM Changing Process.pdf | download |

| RX_RX II Mainboard Changing Process.pdf | download |

| RX_RX II DC Motor Driver Board Changing Process.pdf | download |

| RX_RX II Carriage Changing Process.pdf | download |

| RX_RX II Y-motor changing process.pdf | download |

| RX _RXII X-motor Changing Process.pdf | download |

| RX _RXII Pinch Roller Changing Process.pdf | download |

| RX_RX II Power Board Changing Process.pdf | download |

Reviews

There are no reviews yet.